What Makes Planetary Drives a Popular Choice for Motor Applications?

Key Features of Planetary Drives

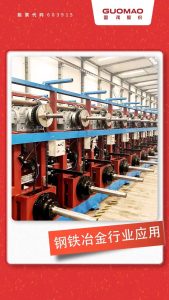

Planetary drives are widely recognized for their design and top-notch performance in a variety of motor applications. Guomao’s planetary drives are earning praise for their compactness and efficiency in particular. Take the Циклоидальный редуктор as an example. The cycloidal reducer adopts the novel transmission mechanism of the planetary transmission principle with a minimal tooth difference and cycloidal pinwheel meshing. It is small in size and convenient to maintain, which makes it ideal for application fields, such as the food processing industry and the steel industry.

These gearbox units have needle bearings on the satellite gears for increased rigidity and lifespan. The IP65 rating also ensures dust and water ingress from any direction.

Advantages of Using Planetary Drives Across Different Motors

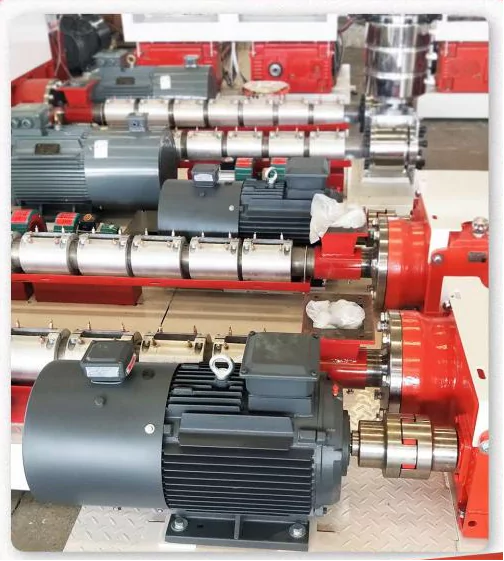

Planetary drives have benefits due to their adaptability to different motor needs while delivering strong performance capabilities. Guomao’s planetary drives feature a selection of speed ratios with a maximum output torque of up to 850,000 kNm for handling tasks, like road construction equipment and tower cranes efficiently.

One other benefit is their ability to minimize noise levels effectively. Guomao’s cycloidal reducers guarantee a smooth operation by using cycloidal pin gears with a high overlap coefficient that reduces vibration and noise significantly. This feature makes them ideal for sectors, like food processing that require operational environments.

How Do Planetary Drives Enhance Performance in Motor Systems?

Efficiency and Precision of Planetary Drives

Efficiency plays a role in motor systems and Guomao’s planetary drives stand out in this aspect. The helical gear sets of Guomao’s products have the ability to offer efficiencies as high as 98 percent and the bevel gear sets are able to offer efficiencies of around 97 percent. This means that there will be less consumption of energy and operational expenses. Guomao’s planetary drives are known for their precision craftsmanship and advanced S-type gear design in precision reducers that boost tolerance levels and extend the fatigue life span significantly.

Torque Capabilities and Load Distribution

Planetary drives are known for being capable of managing torque loads with ease—a defining feature of Guomao’s engineering mechanical planetary gearboxes is the capacity to provide a peak output torque of as much as 850,000 kNm suitable for high-duty applications like rotary drilling rigs or crushers.

The special way planetary drives distribute loads makes them more efficient by splitting the load over several gears to reduce strain and extend the life of the components. The robust design also provides high overload capacity and impact resistance, which are needed for high-starting or direction-changing applications.

Guomao’s pursuit of excellence is apparent from its testing procedures and use of high-quality materials such as bearing steel for transmission components guaranteeing stable performance even under stressful working conditions.

How to Choose the Right Planetary Drive for Your Motor Type?

Factors to Consider When Selecting a Planetary Drive

Compatibility with Motor Types

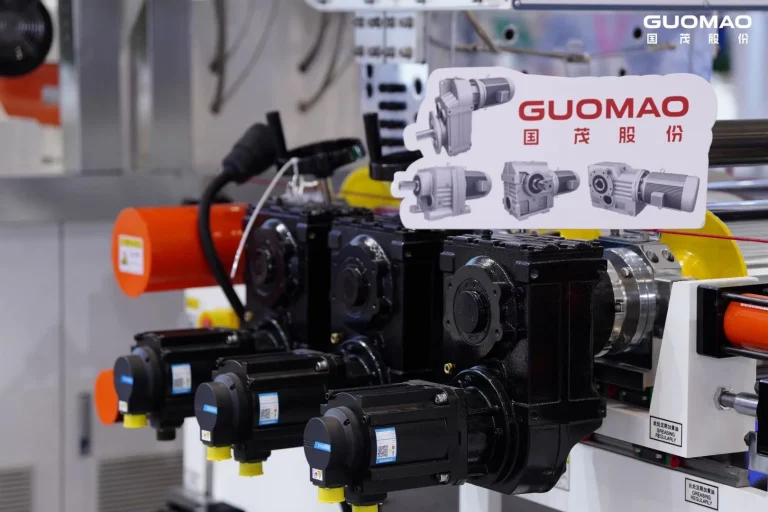

Guomao’s planetary drives feature a design that enhances compatibility even further. А Серия GR Спиральный двигатель has numerous mounting possibilities like foot-mounted and flange-mounted types. Its flexibility makes it ideal for applications such as conveying slurries and driving lifting systems.

Load and Torque Requirements

Knowing the load and torque needs is crucial in selecting a planetary gear system for your application. Assess whether the drive will handle constant, intermittent or shock loads. Planetary drives must match the application’s peak and continuous torque demands to avoid premature wear or failure. Ensure the drive’s rated torque exceeds the system’s maximum operational torque, including safety margins for unexpected overloads. Consider gear material strength (e.g., hardened steel) and lubrication efficiency.

Guomao’s Cycloidal Reducer is particularly effective when dealing with changing load conditions due to its robust overload capacity and resistance to impact forces. It is well suited for tasks that require starting or changes in direction. The balanced distribution of loads among gears helps reduce wear and tear on specific parts of the machinery resulting in a longer lifespan for the equipment.

Why Are Guomao’s Planetary Drives the Ideal Solution for Your Needs?

Unique Design and Engineering Excellence in Guomao’s Planetary Drives

Guomao’s planetary transmissions stand out for their design and high-quality engineering making them a preferred option for a wide range of motor uses. Planetary drives achieve engineering excellence through innovations such as three-stage reduction transmission, which optimizes torque distribution and efficiency for heavy-duty applications. Key highlights include:

- Precision Engineering: Advanced manufacturing processes ensure unparalleled gear meshing accuracy, enhancing durability under extreme loads.

- Robust Construction: Redesigned housings and hardened components deliver exceptional resistance to stress, wear and environmental challenges (e.g., windand dust).

- Tandem Drive Integration: Modular designs enable seamless pairing with tandem drive systems, supporting high-productivity tasks like mining or material handling.

- Adaptive Performance: Optimized for continuous operation in harsh conditions, balancing power density with thermal management to prevent overheating.

Reliability and Durability of Guomao’s Planetary Drives

Guomao’s planetary drives are built with a focus on reliability as their foundation. They are specifically engineered to endure operating conditions while ensuring steady and reliable performance. The sturdy design of these drives helps to reduce damage and preserve their longevity through a method of spreading the workload evenly among various gears. This reduces the need for frequent maintenance.

Customization Options Available with Guomao’s Planetary Drives

Guomao is known for its expertise in offering customized solutions that cater to industrial needs. The flexible design of their planetary gear systems enables a degree of personalization in terms of speed ratios, torque limits and installation setups.

In addition to that, Guomao provides consulting services to assist customers in choosing the best planetary drive for their requirements. Their wide selection of products consist of reducers, mechanical engineering planetary gearboxes and precision planetary reducers which are all crafted to deliver top-notch performance with different types of motors.

Часто задаваемые вопросы about Planetary Drives

Q: What is a planetary drive?

A: A planetary transmission is a special form of geared drive in which the input and output shafts are on the same axis. SIMILAR WORDS: epicyclic gearbox. A three-phase motor drives the front wheels through a planetary transmission. In planetary transmission, one gearwheel orbits around another.

Q: What is the difference between planetary and cycloidal drive?

A: Cycloidal gears work at higher ratios, allowing them to be driven with less power. Planetary Gears are good if positioning accuracy and lost motion are not a concern. Cycloidal Gears are best in applications for high positioning accuracy and a minimum lost motion is required.

Q: What industrial applications are most suitable for Guomao’s planetary drive systems?

A: Guomao’s planetary drives excel in heavy-duty applications where high accuracy and torque density are required, such as construction equipment, mining equipment, and wind power generators. They can be easily integrated into systems with little space because they are compact and modular, and hardened gears ensure reliability in harsh environments like marine or high-vibration conditions.

Q: How do Guomao’s planetary drives address energy efficiency challenges in industrial automation?

A: By optimizing gear meshing and using low-friction materials, Guomao’s planetary drives achieve over 95% mechanical efficiency, reducing energy waste in continuous operations. Their adaptive lubrication systems and thermal management further minimize power loss, making them ideal for automated production lines and renewable energy systems prioritizing sustainability.