What Are the Key Material Factors That Affect Planetary Gear Motor Performance?

Which Metals Are Commonly Used in Planetary Gear Motors?

Which Metals Are Commonly Used in Planetary Gear Motors?

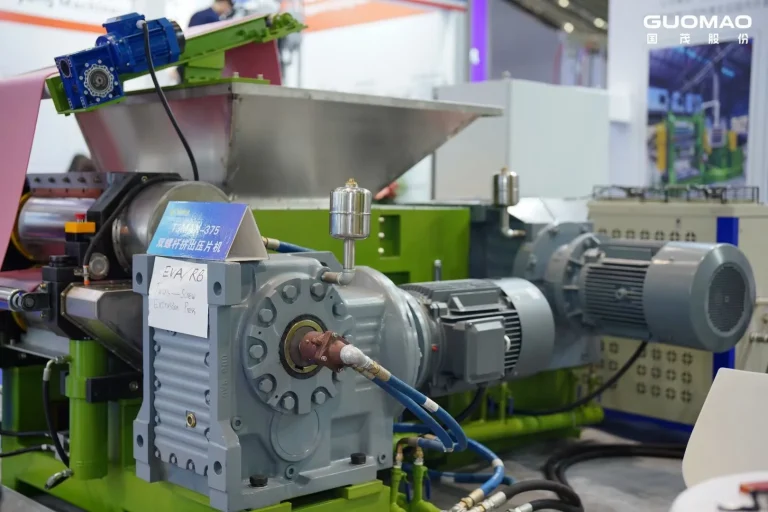

Metals are crucial in the efficiency and longevity of planetary gear motors. Guomao’s Инженерная механическая планетарная коробка передач is made with materials to provide superior reliability in operation. Cast iron is utilized to produce the motor casings with a strong and compact design that can efficiently support heavy radial loads. Gears and shafts undergo gas carburizing followed by precision grinding, enhancing load capacity in compact designs. These processes not only enhance the gear motor’s durability but also significantly extend its operational lifespan.

How Do Surface Treatments Enhance Material Properties?

Surface treatment to improve the performance of planetary gear motors is necessary because it increases the resistance to wear and minimizes friction to a large degree.

Furthermore, methods such as case hardening can enhance the durability of the layer while preserving a strong inner core. This balance of properties is crucial for parts exposed to movement and changing pressures. Through the application of these methods, Guomao guarantees that their planetary gear motors exhibit functionality in a wide range of uses.

Why Is Heat Treatment Critical for Durability?

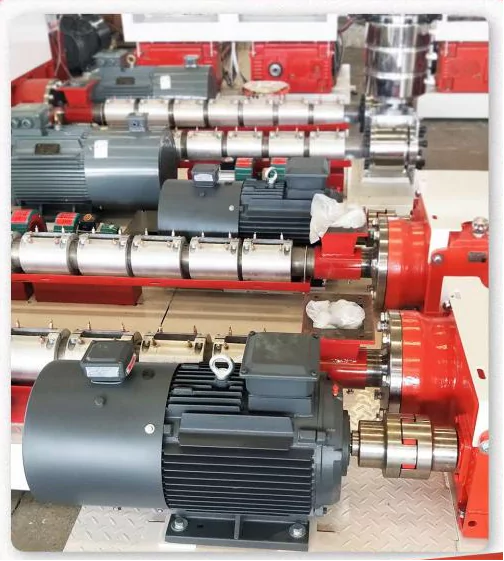

Heat treatment is essential for enhancing the strength and durability of planetary gear motors. Guomao’s gears undergo gas carburizing, a heat treatment process that infuses carbon into the metal surface to enhance hardness and wear resistance. This process enormously enhances the fatigue and wear resistance to ensure that these parts become strong enough to endure usage in working under heavy loads. Heat-treated parts are more resistant to warping or breaking under stress. This makes them especially suitable for demanding industrial applications, such as lifting equipment and conveyor systems. The focus Guomao places on heat treatment during production guarantees that their planetary gear motors perform at their best for the duration of their usage.

Why Is Material Selection Crucial for Prolonging the Lifespan of Planetary Gear Motors?

How Do Different Materials Withstand Wear and Tear?

Material resistance to wear and tear is part of the durability that adds to the lifespan of planetary gear motors, as Guomao’s approach to applying strong cast iron to housings and hardened steel to gears in the Точный планетарный редуктор results in increased resistance to mechanical stress and wear and tear. Moreover, the precision planetary gearboxes from Guomao boast gears that are bolstered by needle bearings with full complement support. These bearings not only increase torsional rigidity but also decrease inner friction. This careful material selection ensures long-term operation with minimal wear and sustained efficiency.

What Role Does Corrosion Resistance Play in Longevity?

Corrosion resistance is essential for extending the service life of planetary gear motors, especially in harsh environments. In order to meet this challenge, Guomao incorporates materials that naturally resist corrosion or coats where needed. For instance, their precision planetary gearboxes come with an IP65 dust and water resistance protection from all sides. Besides, Guomao has also integrated corrosion properties in its products for expected performance even under harsh environmental conditions.

How Does Guomao Ensure High-Quality Materials in Their Planetary Gear Motors?

What Materials Are Utilized in Guomao’s Planetary Gear Motors?

Guomao’s planetary gear motors are designed using materials to prioritize durability and top notch performance levels. They feature housings crafted from cast iron that offer a tough and space efficient structure capable of handling significant radial loads. This careful choice of materials guarantees that planetary gear motors can withstand industrial uses without sacrificing their overall structural strength.

Guomao’s planetary gear motors are crafted with precision to optimize their performance capabilities through a series of steps in manufacturing the gears and shafts involved in the process. The components undergo a gas carburizing treatment and precise grinding to ensure they can withstand loads in a compact design effectively.

How Does Guomao Maintain Stringent Quality Standards?

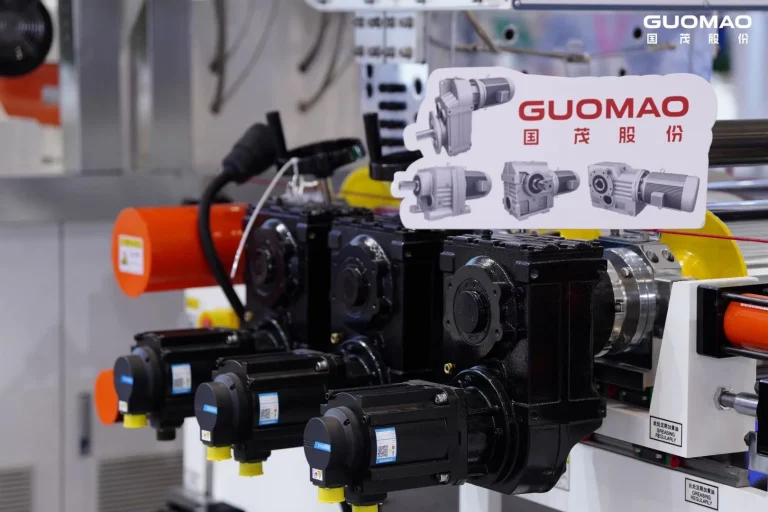

Guomao upholds quality control procedures to uphold the excellence of its planetary gear motor products. All spare parts undergo a quality control assessment to guarantee compliance with ISO9001 certification standards. The dedication to quality is apparent in the manufacturing methods employed across their production operations.

Components such as gears and shafts are inspected both during and after production to ensure quality. For example, to ensure performance under heavy loads, both satellite and sun gears are helical in shape and case-hardened. Furthermore, noise levels are minimized, and efficiency is enhanced through advanced surface treatments such as carburizing and precise grinding techniques.

How Can Choosing Guomao’s Planetary Gear Motors Benefit Your Applications?

Что делает Гумао’s Products Reliable for Long-Term Use?

Guomao’s planetary gear motors prioritize durability and lasting dependability in their design approach. The motor housings are constructed from cast iron to create a durable and space-efficient structure that can withstand significant radial loads. This material selection is crucial for settings that demand reliable performance under intense mechanical strain.

How Does Guomao Optimize Efficiency Through Material Innovation?

Guomao’s planetary gear motor design prioritizes efficiency by utilizing cutting-edge material technologies to enhance transmission efficiency and reduce energy wastage significantly. The gear units crafted by Guomao achieve an efficiency rate surpassing 95%, a testament to the machining and assembly of vital components within their products. Furthermore, the use of full-complement needle bearings with helical gears enhances torsional rigidity and reduces internal friction, significantly improving overall performance efficiency.

Guomao’s unique strategy includes incorporating design principles into its products. The modular construction provides flexibility in transmission ratios and diverse installation options to meet application needs without sacrificing performance quality. Guomao’s use of the most modern material advancements ensures that its planetary gear motors achieve operation efficiency standards.

Часто задаваемые вопросы about Planetary Gear Motor

Q: What is a planetary gear motor?

A: A gear train of planetary gear motor type is one of high power transmission efficiency. It is a configuration of a central gear, sometimes called the sun gear, and several small planet gears or number of planet gears, all housed in a ring gear.

Q: What is a planetary gear used for?

A: Planetary gear sets are used in many applications, from automotive and off-road transmissions to wheel drive motors, industrial conveyor systems, and more. Planetary gear systems are also found in compact mechanisms like electric screwdrivers and automatic transmissions.

Q: What is the difference between a spur gear motor and a planetary gear motor?

A: In addition to their durability, planetary gear motors also provide a higher efficiency than spur gear motors. Because of its configuration, a planetary gear motor is typically more compact and has a higher torque-to-size ratio compared to spur gear motors.

Q: Which industries benefit most from Guomao’s planetary gear motors, and why?

A: These motors work excellently in new energy systems (slurry conveyors and charging stations), hoisting machinery (slewing mechanisms and winches) and conveying equipment. Their wide ratio range and compatibility with radial loads suit dynamic industrial workflows. Applications in lithium battery production, steel mills and food processing highlight their reliability in high-precision, heavy-duty tasks.

Which Metals Are Commonly Used in Planetary Gear Motors?

Which Metals Are Commonly Used in Planetary Gear Motors?