What Makes Helical Gearboxes Essential for Sustainable Manufacturing?

The Role of Helical Gearboxes in Energy Efficiency

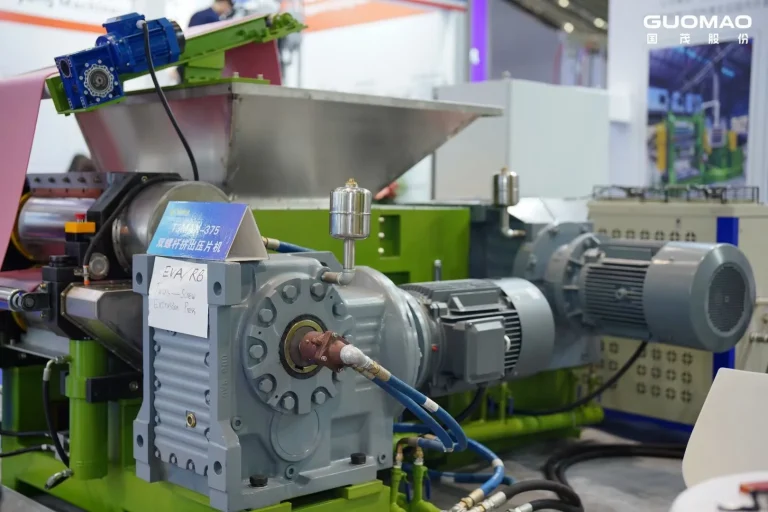

Helical gearboxes help improve energy efficiency in industrial processes by providing high transmission efficiency rates essential for reducing industrial energy consumption. Gear units such as Гумао’с Серия GR Спиральный двигатель achieve an efficiency rate of over 95% and are a perfect fit for industries aiming to save energy. This superior efficiency is achieved through precision machining and careful component assembly that contribute to minimizing energy wastage during use.

In addition, Guomao’s helical gearboxes are designed to accommodate bespoke arrangements for the purpose of satisfying certain operation needs effectively. The gearboxes offer power capacities ranging from 0.12 kW to 200 kW and gear ratios from 1.26 to 33,000. They meet diverse industrial requirements while maintaining optimal performance. This kind of flexibility helps industries to meet their energy requirements without loss of productivity.

How Helical Gearboxes Reduce Operational Waste

Excess wastage is a hindrance in manufacturing processes since it can cause inefficiency and higher cost. Helical gearboxes shatter this hurdle with their capacity to provide performance with low maintenance. Guomao’s helical gearboxes are designed with cast-iron housings and gears that have been subjected to gas carburizing processes. This makes them more durable. This durability lowers replacement rates and reduces material waste. Moreover, the gearboxes’ compactness conserves space in the event of installation in jam-packed factories with minimal space available. Their load carrying capacity is also responsible for seamless operation in diverse applications such as lifting equipment and conveyor belts.

What Are the Long-Term Benefits of Implementing Helical Gearboxes?

Cost Savings Through Efficient Power Transmission

One major benefit of utilizing gearboxes is their capacity to provide long-term cost savings. The design of these gearboxes makes it simple to connect them to motors or power sources easily for different industries to adjust their systems without spending a lot more money on additional expenses. Moreover, different installation choices, like foot-mounted or flange-mounted make it easier to set up the system, saving both time and resources.

Prolonged Machinery Lifespan with Reliable Components

Investment in gearboxes also results in extended machinery lifespan. These products by Guomao are designed for longevity. Key components withstand up to 25,000 hours of operation with proper maintenance. This extended durability decreases the need for replacements and repairs guaranteeing continuous operations.

These gearboxes undergo rigorous testing to ensure long-term dependability, making them ideal for demanding applications, such as slurry conveying or glue machine operation. They put parts through thorough testing to guarantee dependability, which makes them ideal for challenging uses like conveying slurries or operating glue machines. Helical gearboxes play a role in enhancing the reliability of equipment overall. This helps promote manufacturing methods that focus on resource efficiency and lasting benefits.

How Do Guomao’s Helical Gearboxes Enhance Production Efficiency?

Optimizing Performance with Guomao’s Helical Bevel Gears

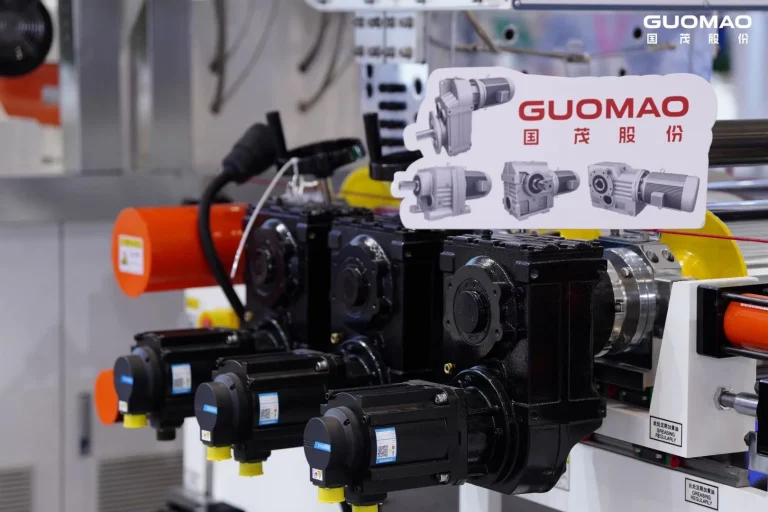

Guomao helical bevel gears are engineered for high performance in demanding conditions. The GK серия спирального мотор с шерстями is evidence of such engineering feat—it merges two-stage helical gears with single-stage bevel gears in order to deliver accurate power transmission and efficiency. This advanced design enables the gearbox to function smoothly and last long enough making it an ideal selection for heavy-duty operating applications. These gearboxes have an advantage in their modular construction in the sense that they can accommodate varying configurations for various types of installations. The modular design allows manufacturers to integrate these gearboxes seamlessly without needing to make extreme modifications.

Guomao’s helical bevel gears are designed for durability as a benefit. They are made from cast iron and have gears treated with gas carburizing processes to withstand tough conditions and heavy loads. This sturdy build not only increases the gearbox’s lifespan but also cuts down maintenance needs resulting in decreased operational costs in the long run.

Reduced noise is a factor in today’s manufacturing plants. The precise crafting and assembly of parts lead to operations that improve the overall comfort of the workplace. Furthermore, the innovative gear design technology guarantees tooth interactions, reducing vibrations and noise levels even more. Guomao’s helical bevel gearboxes are known for their reliability in applications that demand precision and efficiency. This makes them ideal for uses, like conveyor systems and hoisting mechanisms as they greatly improve production processes.

Преимущества Guomao’s Helical Worm Gearbox in Complex Systems

Guomao helical worm gearboxes are engineered with the specificity of meeting complexity in systems and professionalism in mind. The GS-серия спиральных рыночных мотоциклов utilizes stage helical gears in conjunction with single stage worm gears to offer a unique balance of efficiency and compactness, making them ideal for space-restricted environments where restricted space is a crucial aspect to factor.

The strong build of these gearboxes boosts their trustworthiness in certain conditions. With cast iron casings and finely crafted gears in place such gearboxes can tackle hefty radial loads while delivering unfalteringly good performance. This sturdiness reduces downtime and lowers maintenance costs enabling manufacturers to concentrate more effectively on enhancing productivity, which makes these gearboxes suitable for conveying machinery.

Guomao’s helical gearboxes are known for their versatility and efficiency in solving challenges within industrial setups. They are highly valued because they have the advantage of being energy conserving and having long lifespan, which are common benefits for corporations that seek to maximize productivity based on uniform amounts of performance.

Часто задаваемые вопросы about Helical Gearbox

Q: What is a helical gearbox?

A: A helical gear is a cylindrical gear having helicoid teeth, whose teeth incline to the rotation axis. They are similar to spur gears but with the extra benefits of more torque capacity and quiet running. Helical gears transmit power and motion between parallel shafts.

Q: What are the differences between helical and worm gearboxes?

A: Low HP applications are better served with a worm gearbox since it will be significantly less costly. For applications where higher torque is desired (e.g., 10HP at ratio of 30:1), a helical gearbox will be a better alternative. Helical gearboxes consume less power than worm gearboxes.

Q: What is the difference between helical and bevel gearboxэс?

A: Helical Gears: Helical gears, depending on the helix angle, generate axial thrust along the axis of the gear under running. This thrust will have to be supported by appropriate thrust bearings.

Bevel Gears: Bevel gears also generate axial thrust, though typically less than helical gears.

Q: What are the key design features of Guomao’s helical gearboxes that enhance industrial efficiency?

A: Guomao helical gearboxes are masters of modularization, high transmission efficiency (above 90%) and whisper quiet operation. Their multi-stage helical/bevel gear combinations, hollow/solid shaft options and flexible mounting ensure adaptability to diverse industrial setups while handling radial loads up to 50 kNm.