How Does a Helical Gear Reducer Minimize Noise in Machinery?

The Design Advantages of Helical Gear Reducers

Helical gear reducers are designed with special teeth that enable slow meshing between the gears as they progressively engage each other while in operation. This is helpful in noise reduction during gear operation. Unlike spur gears, which engage abruptly, helical gears have inclined teeth that allow continuous force transmission.

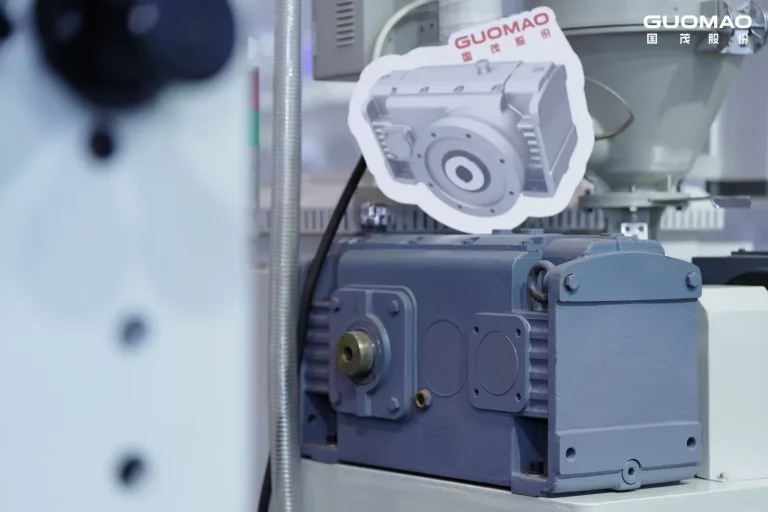

Guomao’s helical gear reducers are industry-leading in noise reduction technology. The gears are made of quenched and carburized hard low-carbon alloy steel for purposes of adding more strength to them. The surface of the tooth is hardened up to HRC 58–62 so that they become usable for longer times without considerable noise. This careful design demonstrates Guomao’s commitment to the most recent noise reduction technology.

Smooth Transmission with Guomao’s Helical Gear Reducers

One notable characteristic of Guomao’s gear reducers is their capability to offer seamless and effective power transfer. They provide maximum energy usage and minimum operating noise with an efficiency of up to 98 % for single-stage systems.

Guomao’s helical gear reducers are perfect for the majority of industries that need precision and reliability since they apply smooth gear engagement and disengagement of gears that minimize wear and tear while maintaining functionality for a very long time.

What Makes Guomao’s Helical Gear Reducer an Optimal Choice for Noise Control?

Key Features of Guomao’s Helical Gear Reducers

Guomao’s helical gear reducers stand out for their capability to evenly distribute loads among teeth during operation. This distributed engagement of teeth improves the load-bearing capacity and minimizes vibrations effectively. Lesser vibrations lead to quieter machinery performance by reducing noise levels. Guomao utilizes high-level production methods to impart tooth alignment and smooth surface finishing to their products. The advancements in technology assist in the longevity of the gear system making it a trustworthy option for industries such as food processing and heavy machine operations.

Performance Testing and Noise Level Certifications by Guomao

Guomao rigorously tests their helical gear reducers to ensure they meet industry standards by evaluating aspects, like transmission efficiency and load capacity across different operating conditions while also assessing noise levels.

How Do Helical-Worm Gearboxes Compare to Other Types in Noise Management?

The Unique Benefits of Helical-Worm Gearboxes by Guomao

Helical gearboxes known for their noise-reducing qualities are highly regarded in the industry. Guomao’s GS Series Helical-Worm Geared Motor is a perfect example of this functionality as it incorporates single-stage helical gears and single-stage worm gears in combination to offer an unbroken and silent transmission process. The clear sliding action of the worm gear minimizes operational noise as compared to normal spur or straight-cut gears.

Guomao’s design incorporates a mix of helical and worm gears to not just minimize noise but also boost the longevity and durability of the gearbox unit. It offers flexibility in the choice of output shafts, hollow shafts with retraction discs or solid shafts, features that increase the reliability of GS series gearbox.

Why Should You Consider a Guomao’s Helical Bevel Speed Reducer for Your Operations?

The Role of Bevel Gears in Further Reducing Operational Noise

Guomao’s GK Series Helical-Bevel Geared Motor is highly acclaimed in efficiency in noise elimination due to its helical bevel speed reducers design feature that employs two-stage helical gears and one-stage bevel gears to produce a smooth and continuous power transmission process. Employing the bevel gear design effectively eliminates vibration during operation to produce a quieter operation of the equipment. Guomao’s cutting-edge engineering guarantees that the bevel gears reach a level of precision in tooth accuracy rated at grade 6, which improves their performance in engagement and effectively lowers the noise levels.

Precision Alignment in Guomao’s Helical Bevel Speed Reducers

Precisely alignment is key for helical bevel speed reducers to perform well at Guomao takes care when putting together their GK series items so that all the parts fit perfectly and reduce any vibrations caused by misalignment which in turn makes the operations run more quietly and smoothly.

What Should Be Considered When Choosing a Helical Gear Reducer?

Why is Transmission Efficiency Crucial in Selecting a Helical Gear Reducer?

Why is Transmission Efficiency Crucial in Selecting a Helical Gear Reducer?

A gear reducer with high efficiency minimizes energy wastage during operation. Allows more power to be transferred to the output shaft. Guomao’s helical gear reducers are characterized by their high transmission efficiency of up to 98% in single-stage configurations. Guomao’s first consideration in the design of their helical gear reducers is efficiency and precision engineering. The gears are manufactured from high-strength carbon alloy steel by carburization and quenching for long life and consistency in performance for years to come.

How Does Load-Bearing Capacity Influence Your Choice?

When selecting a gear reducer, its load-carrying capacity must also be considered. The capacity to carry loads is necessary to utilize in heavy machinery and industrial environments. Guomao’s helical gear reducers stand out in this regard thanks to their design elements. Guomao’s products utilize a technology in which the teeth work together to distribute loads evenly during use. This technology not only increases the carrying capacity but also minimizes wear and tear on the machine parts.

Why is Noise Reduction Important in Industrial Applications?

Noise attenuation is also critical in industrial use to ensure seamless operations and minimize disrupting vibrations, which could ruin equipment or impinge on accuracy. By absorbing vibrations and noise, systems are quieter, with less wear on parts and longer equipment life. This also creates a safer working environment by lowering risks linked with excess noise levels.

Frequently Asked Questions about Helical Gear Reducer

Q: What is a helical gear reducer?

A: Helical gear reducer is one gearbox with helical gear shape and can reduce the output speed and increase the torque for transmission. It exists in two types: reducer motor plug-in and dual-shaft reducer.

Q: What are gear reducers used for?

A: A gear reducer is a speed reducer that changes the rotational speed using gears, shaft positioning, and the arrangement of gears. They are widely used with reduction transmission equipment where the transmission structure integrates the drive motor and the gearbox or gear reducer.

Q: Does a gear reducer increase torque?

A: For devices that require acceleration at high speeds, torque can not be overemphasized. This is achieved through gear reducers because they can boost the torque exponentially through the number of teeth in each gear and the number of gears in the system.

Q: Which industries benefit most from the GR Series Helical Geared Motor?

A: The GR Series is widely used in conveying machinery (bucket/screw/belt conveyors), hoisting systems (lifting mechanisms and slewing drives), and new energy equipment (charging systems and glue machines). Its compact structure and shock resistance suit steel mills, while high precision and low vibration meet food processing or homogenizing equipment needs. Modularity and multi-stage gear combinations also make it adaptable to lithium battery production or wastewater treatment, ensuring reliable performance in high-load, high-efficiency scenarios across industries.

Why is Transmission Efficiency Crucial in Selecting a Helical Gear Reducer?

Why is Transmission Efficiency Crucial in Selecting a Helical Gear Reducer?