What Are the Historical Roots of Planetary Gear Systems?

The Origins of Planetary Gear Mechanisms in Ancient Civilizations

Planetary gear systems are also referred to as gear trains. Their origins can be traced back to ancient civilizations with roots in Mesopotamia and advancements by Greek and Roman innovators throughout history. The innovative concept of employing interlocking gears for motion and torque transmission pioneered the foundation of contemporary mechanical engineering as we know it today. Evidence from ancient texts and artifacts reveals the existence of primitive planetary systems integrated into tools, such as water clocks and initial astronomical devices.

How Ancient Engineering Principles Shaped Modern Gearbox Design

Ancient engineering concepts highlighted the importance of simplicity and robustness in gearbox design—an approach that continues to influence engineering practices today. The planetary transmission concept features a sun gear surrounded by orbiting planet gears and external ring gear to provide efficient torque transmission within a compact framework.

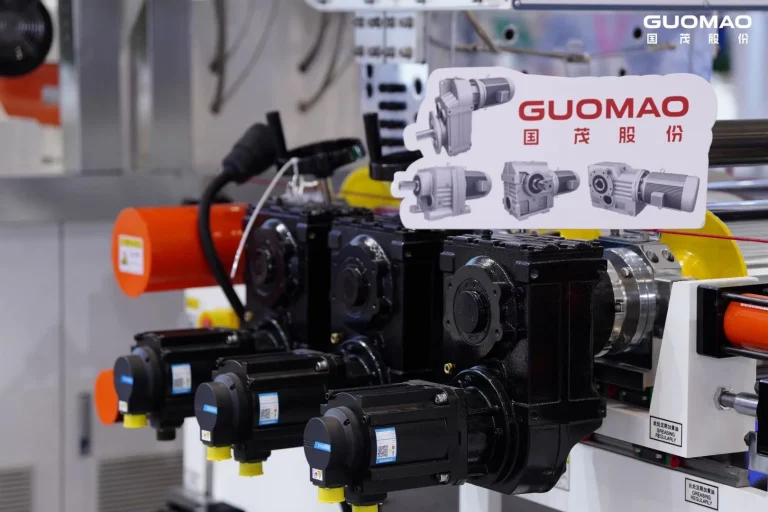

Guomao’s Precision Planetary Reducer showcases a timeless design approach that sets them apart in the industry. These gearboxes stand out for their size and efficient planetary design which align the input and output shafts along a single axis for optimal use of space. Additionally, the inclusion of S-type gears not only increases tolerance but also enhances their durability.

Guomao’s Integration of Historical Concepts into High-Precision Planetary Gearboxes

Guomao has integrated traditional ideas into its modern products by incorporating helical shaped planet and sun gears in our advanced precision planetary reducers to achieve superior transmission outcomes—a practice rooted in centuries old principles of excellence and innovation. The gears are hardened to a level of 58 to 62 HRC to guarantee outstanding longevity and functionality even in demanding environments.

How Do Ancient Innovations Contribute to the Performance of Modern Precision Planetary Gearboxes?

The Influence of Ancient Load Distribution Techniques on Guomao’s Designs

Ancient societies showed creativity in creating devices that effectively spread weight over various areas. A technique seen in early tools such as watermills and clock mechanisms, which has greatly impacted present-day engineering practices.

Guomao applies these time-tested principles to its precision planetary gearboxes, ensuring meticulous craftsmanship. A sun gear is paired with planet gears, together with a ring gear for distributing the load using the planetary gear configuration applied within these gearboxes. The setup maximizes the operating efficiency in this specific structure. For Guomao’s helical gear sets, the efficiency rate can be as high as 98%, not only reducing energy consumption while lowering operating costs for enterprises based on such systems. Such gearboxes offer torque transmission abilities with a speed ratio of 30 to 160 in order to meet various operational requirements in fields like robotics aerospace and machine tools. Their flexibility underlines their significance as components in advanced machinery.

Balancing Speed and Accuracy: Lessons from Historical Mechanisms Applied by Guomao

Our products can be combined with functions such as supporting planet gears equipped with full complement needle bearings to enhance torsional rigidity to ensure accurate motion control, even at high speeds. Guomao stands out in the realm of noise reduction well by incorporating low noise profiling technology in its gearboxes inspired by historical mechanisms known for their quiet operation. This not only improves user satisfaction but also minimizes operational disturbances in settings where silence is crucial.

Drawing upon insights from the past while leveraging state-of-the-art technology, Guomao has established standards within the field. Our advanced planetary gear systems aren’t merely devices but rather remarkable feats of engineering that embody generations of wisdom and inventive thinking.

Why Choose Guomao for High Precision Planetary Gearbox Solutions?

Tailored Solutions for Diverse Industrial Applications

Customization Options to Meet Specific Needs

Guomao is well known in the industry for its expertise in offering customized high precision planetary gearbox solutions for a diverse array of industrial needs. Our Precision Planetary Reducer is distinguished by their S type gears that boost tolerance and greatly enhance durability. All of our planet and sun gears are spiral-shaped. The planet gears are double supported with full complement needle bearings for increased torsional stiffness.

Guomao prioritizes flexibility not only in their products but also in their production methods providing a range of installation choices, such as flange installation and direct motor connection options to seamlessly fit into current setups.

Enhanced Reliability for Critical Operations

Guomao places importance on the reliability of its products and focuses especially on situations where consistent performance is crucially important. The key parts of their gearboxes are made from materials such as carburized steel to ensure longevity even when handling heavy loads. This sturdy design helps reduce downtime and improves operational effectiveness.

Proven Quality Standards Backed by Advanced Testing Technologies

Guomao demonstrates its commitment to excellence through rigorous testing procedures and strict adherence to global standards. Each of these parts goes through quality checks to guarantee they achieve the highest performance standards. We also perform full-load fatigue assessments at extreme rated torque levels to confirm the accuracy of gear load capacity calculations and to assess the quality of materials used in product manufacturing and assembly accuracy. By focusing on quality control procedures, Guomao ensures that their high-end planetary gearboxes offer reliable performance in challenging conditions consistently.

You can count on our pioneering methods to deliver products that are finely tuned to cater to industrial requirements. If you have any questions, contact us!

Frequently Asked Questions about High Precision Planetary Gearbox

Q: What is the purpose of a planetary gearbox?

A: Planetary gearing is employed in harsh applications because the three planet gears are evenly distributed around the sun gear. They are stronger and power-denser, with less ability to be able to withstand greater torques and ratios in a compact, smaller package.

Q: Are planetary gearboxes strong?

A: If you require an industrial gearbox solution that is durable, a planetary gearbox is ideal. The modular and innovative design of the machine offers several advantages for heavy-duty applications. The equipment becomes resistant to damage from high-torque applications.

Q: How to improve gearbox efficiency?

A: Lubrication: It is among the most vital conditions that help to improve gearbox efficiency and performance. Gearbox lubrication plays several roles, including reducing friction, preventing wear, and conducting heat. Incorrect lubrication or improper lubrication can lead to early wear and even failure.

Q: What are the key advantages of precision planetary reducers in industrial applications?