The Role of Planetary Reducers in Modern Machinery

Importance of Precision and Efficiency

Planetary reducers play a critical role in modern machinery by ensuring optimal precision and efficiency, resulting in improved production outcomes. The compact design of planetary reducers minimizes power transmission losses, allowing machines to operate at peak efficiency while reducing wear. The reducer’s hardened gears (58–62 HRC) ensure maximum transmission efficiency, reliability and high performance, making it an ideal choice. This corresponds with the need for high-tech machinery in industries like construction, where accurate torque control and smooth speed control are essentials to operations like automated assembly or heavy load control.

By integrating planetary reducers, systems achieve higher productivity through reliable power distribution, reduced downtime and adaptability to variable operational demands. Their role in modern innovations underscores their importance as a cornerstone of efficient, high-performance machinery. It is widely used in sectors including robotics in industries, like machine manufacturing and aerospace.

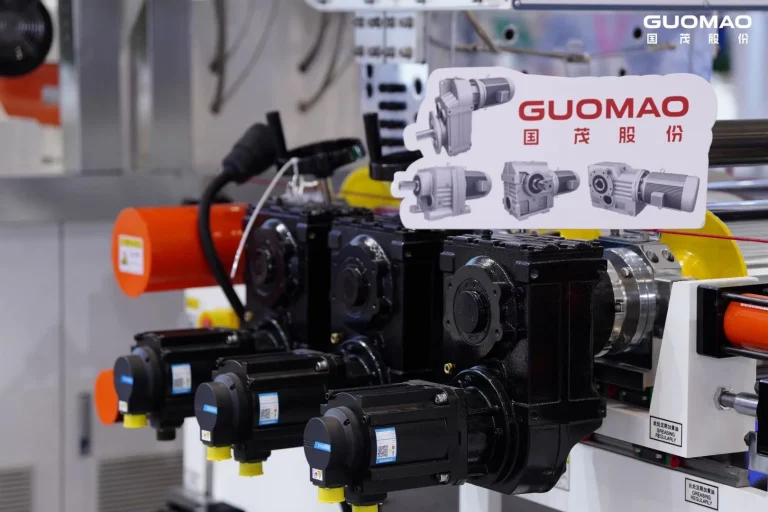

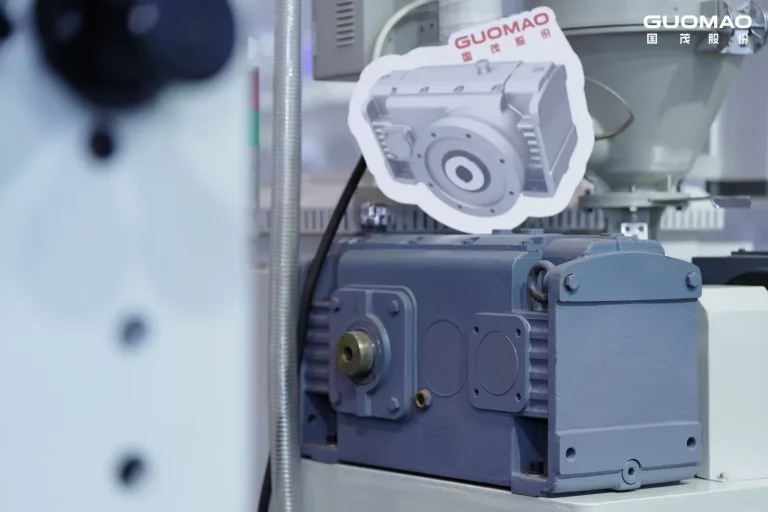

Guomao’s Contribution to Planetary Reducers

Guomao has established itself as a leading manufacturer of planetary gear reducers, renowned for innovative designs and high-quality standards. For example, the Precision Planetary Reducer by Guomao holds an ISO9001 certification. Guomao’s design features double-support satellite gears paired with full-complement needle bearings, significantly enhancing torsional stiffness. This setup greatly improves rigidity and lowers the noise levels significantly. Guomao’s precision planetary gearboxes achieve an IP65 rating, ensuring protection against dust and water ingress. This means protection against dust infiltration and water jets which are emitted from a nozzle and sprayed against the housing from all directions.

Key Features of Low-Cost Planetary Gearboxes

Cost-Effectiveness without Compromising Quality

Low-cost planetary gearboxes deliver high torque output in compact designs, ideal for space-constrained applications requiring significant power. A key highlight of Guomao’s product range offering cost-effective solutions with compact planetary designs that pack a punch in torque output despite their small size making them perfect for situations where space is a premium but power needs are significant. Their design reduces mechanical vibration and ensures a low failure rate, significantly cutting maintenance needs and operational downtime. By optimizing power transmission, these gearboxes enhance energy utilization, aligning with streamlined efficiency goals in industrial applications.

Technological Innovations by Guomao

Guomao is constantly innovating in the realm of technology through its gearbox design advancements and features that boost durability and extend product longevity by enhancing tolerance levels and fatigue resistance. This innovation also includes Speed ratios ranging from 30:1 to 160:1 provide tailored solutions for specific operational needs. that cater to specific operational requirements. These technological strides maintain Guomao’s leading position in the industry by delivering effective solutions for the evolving needs of modern machinery. The Engineering Mechanical Planetary Gearbox combines compact size with high torque, offering a speed ratio range of 3.4:1 to 2500:1.

Advantages of Using a Planetary Reduction Gearbox

Enhanced Torque and Load Capacity

The planetary reduction gearbox is highly regarded for its increased torque and load-bearing capabilities which are essential in a wide range of industrial settings. Guomao’s planetary gearboxes are meticulously crafted with precision. Get helical gears hardened to 58–62 HRC for optimum transmission performance. The sturdy design enables the gearboxes to easily handle torque outputs and is well suited for heavy-duty applications like driving road building equipment, tower cranes, and hoisting machinery.

Guomao’s commitment to excellence is evident in its satellite gears, which feature full-complement needle bearings that significantly enhance torsional stiffness. This innovative design boosts load capacity while guarantee an operation even under heavy loads thus prolong the machinerys lifespan.

Space-Saving Design Benefits

Unlike traditional reducers, planetary gearboxes excel in space efficiency due to their compact, coaxial design, reducing footprint by up to 30% while maintaining high power density. Planetary reduction gearboxes excel in space efficiency due to their compact, coaxial design (input/output shafts aligned on the same axis), minimizing footprint while maximizing power density. This aligns with the cycloidal reducer’s features, such as “small volume” and “modular installation” (flange, foot-mounted or direct motor coupling), enabling seamless integration into tight machinery layouts.

Maintenance and Longevity of Guomao’s Planetary Reducers

Simplified Maintenance Procedures

Guomao’s planetary gearboxes are created with user maintenance processes in mind to appeal to industries looking for dependable and effective solutions. They are designed with a structure that enables effortless assembly and disassembly for maintenance purposes. This user-friendly maintenance approach is essential for reducing equipment downtime and guaranteeing efficient machinery operation. Additionally, the incorporation of double-supported satellite gears with full-complement needle bearings increases torsional stiffness, contributing to the longevity of the equipment.

Longevity and Reliability in Harsh Conditions

Guomao’s planetary gearboxes are built to handle environments and are a dependable option for a range of industrial uses. Their durability is thanks to top notch materials and designs that enable these gearboxes to function efficiently even in difficult conditions.

Furthermore, the commitment of Guomao to quality is clear in how they follow manufacturing standards in their operations. This is seen in the certification for products which ensures that every component goes through thorough quality control procedures. This dedication to excellence assures customers that Guomao’s planetary reducers are not only just dependable but also capable of providing consistent performance over long durations.

Frequently Asked Questions

Q: What is a planetary gear reducer?

A: A planetary gear reducer uses planetary gears to reduce input motor speed while increasing output torque or other. Reducers are utilized in machinery used in industries to achieve precise speed ratios (e.g., 1:658,503) between output and input shafts.

Q: How does a planetary gear reducer work?

A: Planet gears are installed on a carrier, which is secured by an output shaft. The sun gear rotation and stationary carrier make the planet gears move around the sun gear and thus produce a reduction in gears during the process. During the process, the output shaft rotates more slowly than the input shaft but with greater torque.

Q: What are the key features and industrial applications of the Precision Planetary Reducer?

A: Precision Planetary Reducer provides high torque density and multi-stage ratio for precision motion control. It is modular and compact in design to reduce inertia and ensure silent running in hostile environments like steel mills, food processing and production of lithium batteries. It can be applied to conveyors, mixers and automatic machinery with high efficiency (>90%) and minimum backlash.

Q: How does the precision planetary reducer ensure durability in harsh conditions?

A: With hardened bearing steel gears and enclosed lubrication assemblies (grease or oil bath), it resists heavy loads, start/stop cycling, and severe temperatures. Multi-gear engagement and corrosion-resistant housings provide longer life in wastewater treatment and mining environments for instance. Mounting adjustability (flange, foot or direct motor coupling) and ISO-certified fabrication also ensure reliability in rugged operating environments.