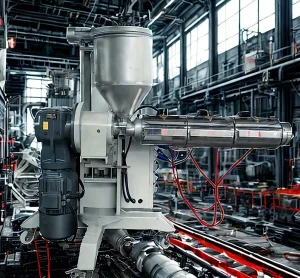

Enhancing Efficiency with Helical Bevel Gearboxes

The Role of Helical Bevel Gears in Mechanical Systems

Helical bevel gears improve mechanical systems through their unique design and helical teeth, which reduce vibration and noise compared to straight-cut gears. This makes them particularly suitable for precision applications such as conveyors, renewable energy machinery (e.g., wind turbines) and hoisting systems. Key roles include:

- Directional Flexibility

Enables vertical orientation of input/output shafts (e.g., in winches or slurry conveyors).

- High Load Capacity

Hardened helical bevel gears withstand radial loads and high torque (up to 50 kN·m), meeting the demands of industrial heavy-duty applications.

- Durability

High-precision gears ensure extended service life under repetitive stress, making them ideal for demanding applications such as homogenizers and adhesive processing systems.

- Compact Design

Modular construction and small volume allow integration into space-constrained systems without sacrificing performance.

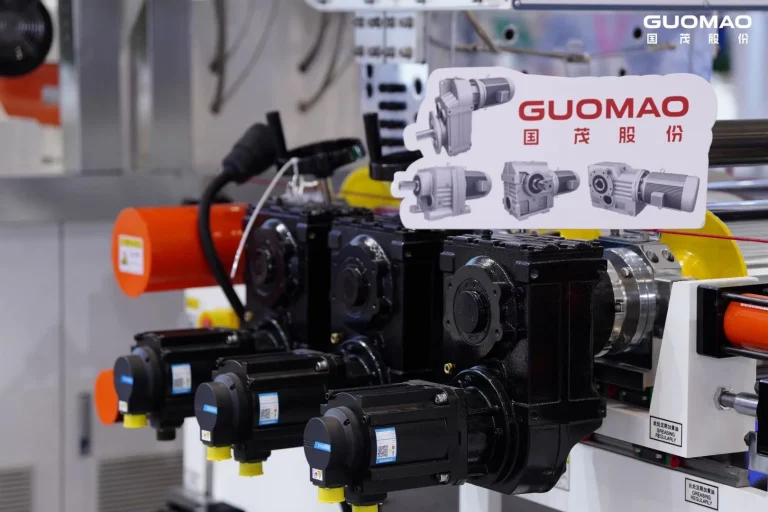

Guomao’s Helical Bevel Gearbox: A Closer Look

Guomao’s GK Series Helical-Bevel Geared Motor leads in its class with its unique features setting it apart from other equipped motors. The output shafts are at right angles to the input shafts. It has two-stage helical gears and one-stage bevel gear per unit. The GK series gearbox offers foot-mounted, B5 flange-mounted, B14 flange-mounted, shaft-mounted and torque arm-mounted configurations. It has various input shaft designs and comprises combinations of helical gears and bevel gears. The output shafts include hollow shafts with locking discs and solid shafts. It has a wide range of transmission ratios and a high transmission efficiency.

Improving Power Transmission with Guomao’s Solutions

Understanding the Mechanics of Power Transmission

The transmission of power plays a role in every mechanical system. Guomao’s helical bevel gearboxes stand out in this aspect due to their superior efficiency levels. These gear units boast an efficiency rate exceeding 95%, surpassing that of other gear units on the market.This remarkable efficiency is attained through the machining of components and precise assembly procedures coupled with thorough testing processes to guarantee peak performance.

Applications of Guomao’s Helical Bevel Gearmotors

Guomao’s helical bevel gear motors are highly versatile and widely used across various industries. They play a role in powering new energy equipment and charging systems as well as in processes like homogenizing equipment and glue machine systems. Besides, they are also essential components of slurry conveying systems and hoisting machines. In addition, these gear motors are made to deliver high performance even in harsh conditions such as temperatures ranging from -10°C to 40°C and altitudes of up to 1000 meters above sea level.

Guomao helical bevel gearboxes optimize mechanical systems with modern design and multitasking capabilities. They are highly efficient in transmitting power while keeping noise levels minimal which greatly benefits optimizing industrial processes.

Durability and Longevity in Mechanical Systems

Factors Affecting Gearbox Longevity

The durability of a gear transmission system critically influences the reliability and environmental friendliness of mechanical setups. Guomao’s helical bevel gearboxes are crafted to withstand the test of time; their key parts can last for over 25,000 hours through upkeep and operation. The cast iron casings and gears treat with a gas carburizing method before precise grinding is applied. These manufacturing processes bolster the load bearing capacity per unit volume significantly. Greatly enhances the gearbox’s resilience.

Also, the gearboxes of the Guomao have efficient components that allow them to achieve over 95% efficiency in their gear boxes.Not only do the high efficiencies increase power transmission but also lower stress and damage that could be inflicted on the parts of the gearbox to result in a longer lifespan.

By incorporating Guomao’s helical bevel gearboxes into machine designs, businesses can enhance performance efficiency while minimizing maintenance demands. Combining the maximum in transmission efficiency with unmatchable ruggedness and flexibility, these transmissions are a key factor in maximizing mechanical process efficiency and lifespan.

Cost-effectiveness and Economic Impact

Evaluating the Cost Benefits of Helical Bevel Gearboxes

Guomao’s helical bevel gearboxes offer economic advantages through enhanced cost-effectiveness of the mechanical parts. They possess modular shapes that can be readily integrated with different kinds of motors or source powers. This allows the use of a single motor type to drive diverse power requirements to drive diverse motor powers. This enables companies to implement customized solutions without purchasing specialized components separately.

Besides, such transmissions possess over 95% transmission efficiency, reducing energy consumption. This reduces operating expenses in the long run.

Strategic Advantages for Businesses Using Guomao’s Gearboxes

Guomao’s helical bevel gearboxes offer businesses a competitive edge through superior performance and reliability. The gearboxes have a lifespan where key components can be serviced for over 25,000 hours if properly maintained. This minimizes downtime and maintenance costs. The longevity of the gearbox is derived from the material, including cast iron housings and precision-made gears.

Guomao demonstrates a dedication to ensuring the quality of their gearboxes by performing aggressive testing processes prior to their utilization. This rigorous approach allows companies to rely on their systems to function effectively and efficiently for long periods.

By investing in Guomao’s helical bevel gearboxes, businesses not only benefit from immediate. If you are interested in Guomao’s products, please feel free to consult us. We are dedicated to providing you with high-quality and efficient services.

Frequently Asked Questions

Q: What is a helical bevel gearbox?

A: Helical bevel gearboxes are often employed in baggage conveyors, rope lifters and industrial mixers because of their small size and great power density. Their engaged teeth ensure stable power and energy transmission.

Q: What is the use of a helical gearbox?

A: Helical gearboxes are generally used on machinery where actions need to work at higher speed ranges (hotel & catering industry machinery) or lower sound levels (automotive or air conditioning industries). They are also widely used on machines where there is a need for transmitting high torque between parallel axes.

Q: What are the advantages and disadvantages of helical gears?

A: Helical gears have better load-carrying capacity and smoothness and quietness of operation, because of sliding action of the meshing teeth. The sole disadvantage, however, is added friction and wear with this sliding action.

Q: What are the key features and applications of the GK Series Helical-Bevel Geared Motor?

A: The GK Series combines helical and bevel gears, offering vertical alignment of input/output shafts. Key features include modular design, high precision, low noise and a wide transmission ratio range (1.26–33,000). It supports multiple installations (foot-mounted and flange-mounted) and handles up to 50 kN.m torque. Applications span hoisting machinery, conveyors and renewable energy systems like slurry conveying and charging equipment.