The Advantages of Helical Gear Motors in Industrial Applications

Improved Efficiency and Torque Transmission

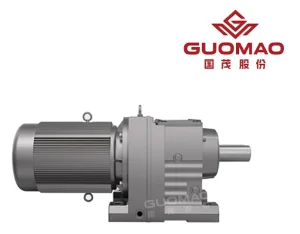

Guomao’s helical gear motors are widely recognized for their efficient and precise torque transmission, ensuring high reliability. GR series motors have a good name for better transmission efficiency and smoothened operation under radial loads as a result of the excellent design quality of the motor. Its slanted teeth design facilitates a mesh process leading to smoother transmission dynamics and less energy dissipation when compared to traditional straight gear configurations.

Guomao’s helical gear reducers provide transmission ratios that effectively fulfill industrial requirements. These gear motors are highly adaptable due to their modular design and various mounting options, making them suitable for diverse applications, including renewable energy systems and material handling equipment.

Noise Reduction and Smooth Operation

Helical gear motors are known for their quiet and smooth operation, especially when compared to straight gears or other gear types.The GR series helical geared motor is precision manufactured.

It is assembled with care to run quietly. The teeth of these gears are specially shaped so that they engage more smoothly compared to straight-cut toothed gears with less vibration and noise during operation. This makes it particularly useful in areas where the minimum disturbance is wanted – for example, food processing plants or pharmaceutical manufacturing plants.

Durability and Longevity in Harsh Environments

These geared motors are designed to withstand tough industrial conditions, providing durability and long-lasting performance that regular gears may struggle to match. Guomao’s GR series helical geared motor is designed for durability, ensuring a lifespan of over 25,000 hours under normal operating conditions. The motors have cast iron housings that render them resistant to wear and tear.

Also, the unique method of locking the gears improves their ability to withstand loads in small spaces which is ideal for heavy-duty operations such as running lifting machines or pumping fluids.

Comparing Helical Gear Motors with Straight Gears

Performance Metrics: Helical vs. Straight Gears

The design is simple, making straight gears highly economical and inexpensive to produce. Straight spur gears do generate a lot of noise and vibration at high speeds and thus are ideal for low-speed usage. Helical gear motors are quieter and smoother in operation due to the gradual engagement of teeth because the angled teeth engage in a gradual manner, reducing impact and vibration.

Cost-Benefit Analysis for Industrial Use

When purchasing gear motors with gears at first glance the initial costs might seem high. However, in the term, the advantages typically surpass these expenses because of their improved efficiency which results in saving energy over time.

Exploring Guomao’s Helical Gear Motor Product Line

Key Features of Guomao’s Helical Gear Motors

Guomao’s helical gear motors have been carefully crafted to offer a range of transmission ratios and installation choices to meet various needs effectively. This adaptability is expressed in the GR series geared motors that allow the customers to have either foot-mounted or B5 flange-mounted configurations. The adjustable design and mounting of the gear motors allow them to fit into a number of applications including new energy machinery and conveying devices. These motors are widely recognized for their precision and low noise, achieved through high-precision machining and meticulous assembly. Guomao’s helical gear motors possess capacity in terms of power that ranges between 0.12 kW and 200 kW. They provide the highest output torque of up to 50 kN.m catering to a range of industrial applications with maximum emphasis on reliability and effectiveness. The gear unit boasts an efficiency rating of over 95% whereas the worm gear unit can achieve efficiencies as high as 89%.

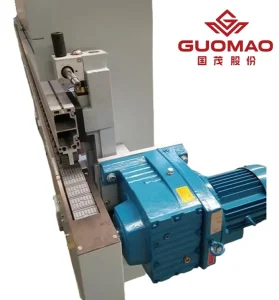

Application Scenarios for Guomao’s Helical Inline Gearbox

Guomao’s helical inline gearbox is designed to cater to the requirements of environments because of its robust construction and adaptable features. The gearboxes in the GR series come with input and output shafts positioned off-center. These units in the GR series are fitted with either a stage or three-stage helical gear arrangement. This configuration enables the gearbox to handle operations across different industries.

Energy technology advancements rely heavily on gearboxes that play a crucial role in different systems such as charging stations and mixing equipment by efficiently handling heavy loads. They are commonly used in applications like slurry conveyance systems and tasks involving machinery. In lifting equipment scenarios they perform tasks like movement mechanisms slewing motions and lifting mechanisms.

In addition to that gear reducers made by Guomao are widely used in types of conveying equipment, like bucket conveyors screw conveyors, belt conveyors and winches because of their strong durability that allows them to work effectively even in challenging conditions.

Frequently Asked Questions about Guomao’s Helical Gear Motors

Q: What Makes Guomao’s Helical Gear Motors Stand Out?

A: Guomao’s helical gear motors are designed with a modular construction that accommodates several types of installation such as foot-mounted or flange-mounted types.

Guomao offers a range of helical gear motors ranging from 0.12 kW to 200 kW that can deliver a maximum output torque of up to 50 kN.m and can be used to meet various industrial demands reliably. The gear unit is quite impressive with an efficiency of more than 95% while the worm gear unit can achieve as much as 89% efficiency.

They have a wide range of transmission ratios and precise operation, which enables them to be widely applicable for all kinds of industrial use from new energy equipment to conveying equipment.

Q: How Can I Select the Right Helical Gear Motor for My Needs?

A: When selecting a gear motor to match your requirement, there are several things to consider such as requirements for power, available space for installation and application of the motor. Guomao’s helical gear motors are designed with flexibility so that various mounting types like foot mounted or flange mounted types can be allowed. They supply transmission ratios and operate with high accuracy making them ideal for numerous industrial applications starting from renewable energy systems to conveyor equipment.