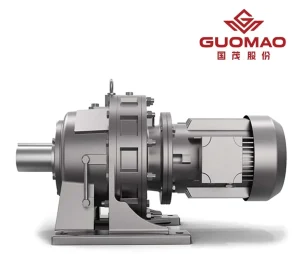

The Advantages of Guomao’s Cycloidal Gear Reducer

Compact Design Benefits

Guomao’s cycloidal gear reducer is recognized for its compact design, achieved through the planetary transmission principle, which aligns the input and output shafts along the same axis. This design not only conserves space but also allows for easy incorporation into various mechanical configurations without structural modification. These features make it a great choice for textile printing and dyeing industries where space efficiency is of utmost importance.

Durability and Reliability

Guomao’s cycloidal gear reducer delivers long-lasting high performance, thanks to its key transmission components made of premium bearing steel, known for its excellent mechanical properties, which help reduce friction and extend equipment lifespan.

Efficiency in Operation

Guomao’s cycloidal gear reducer is known for its efficiency as well as its ability to achieve high reduction ratios with efficiency levels above 90% in single-stage transmissions with a ratio of 1:87. In cases where greater reduction ratios are needed, multi-stage transmissions can be used. This increased efficiency translates into long-term energy savings and reduced operational costs.

The Technology Behind Guomao’s Cycloidal Gear Reducer

Unique Mechanism of Cycloidal Gear Reducers

Guomao’s cycloidal gear reducer features a transmission system inspired by planetary transmission concepts, with minimal gear variations involved in the process. The utilization of needle and gear meshing plays a significant role in its functionality across various industries, including metallurgical mining, petrochemicals, and engineering machinery applications. This distinct mechanism enables operation even in scenarios demanding frequent starting and reversing actions.

Components and Materials Used by Guomao

Guomao’s cycloidal reducer is built with parts such as the output shaft, fastening ring, small end cover, machine base, pin shaft and pin sleeve. Each of these components is carefully crafted to allow for assembly, disassembly and upkeep. By utilizing premium-grade bearing steel, renowned for its exceptional wear resistance and mechanical strength every piece plays a role in enhancing the longevity and efficiency of the reducer.

Applications of Guomao’s Cycloidal Gear Reducers in Various Industries

Industrial Machinery Applications

Guomao’s cycloidal gear reducers find application in a number of industrial machine applications due to their high-level performance features and efficiency levels for use across industries like textile printing and metallurgical mining, among others. The precision-engineered pin gear structure ensures smooth operation with minimal noise, making it ideal for noise-sensitive industrial environments. Moreover, the robust overload capacity and resistance to impacts guarantee that these gear reducers can manage the requirements of industrial tasks effectively.

Renewable Energy Sector Utilization

Guomao’s cycloidal gear reducers are vital in boosting the efficiency and dependability of equipment like wind turbines within the energy industry sector. Their compact design and small size make them easy to incorporate into turbine setups without sacrificing functionality. With durable construction and extended service life, these reducers ensure consistent energy generation while their robust performance maximizes output.

Robotics and Automation Solutions

Guomao’s cycloidal gear reducers help advance the robotics and automation sector through low inertia moments essential for precision movement and fast response times. They are easily assembled and maintained, enabling easy integration into robot systems and minimizing downtime for maintenance or upgrades. Furthermore, the capability to manage starts and reversals makes these reducers perfect for dynamic automation operations.

Choosing the Right Guomao’s Cycloidal Gear Reducer for Your Needs

Factors to Consider When Selecting a Model

When selecting a cycloidal gear reducer for your application and to attain the performance achievable there are some important considerations to remember. First, the preferred reduction ratio can be tailored by using either a single-stage or multi-stage transmission depending on what your requirement is. Second, the type of input connection is important too – you have options like biaxial or motor direct coupling to match different mechanical setups. Third, knowing the specific requirements of your industry application will help you decide between installation styles such as flange or anchor setups.

Customization Options Offered by Guomao

Guomao provides a variety of customization capabilities to meet various industry demands. For example, the parameter of the Cycloidal Reducer can be customized from 0.12 kW to 90 kW. In addition, the possibility of nonstandard customization ensures that specific design needs can be met without compromising reliability or performance.

Frequently Asked Questions About Guomao’s Cycloidal Gear Reducers

Q: What makes Guomao’s cycloidal gear reducers stand out from competitors?

A: Guomao’s cycloidal gear reducer features a compact design due to its transmission method, which aligns the input and output shafts along the same axis, enabling a smaller volume that can be directly integrated into limited mechanical environments without requiring extreme modification. The engagement between needle and gear enhances their reliability in numerous industries, including textile printing, dyeing, metallurgical mining and petrochemicals.

Moreover, Guomao’s cycloidal gear reducers provide ratios and efficiency levels are also high with single-stage transmission achieving a reduction ratio of 1 to 87 and efficiency exceeding 90%. For applications requiring higher reduction ratios, multi-stage transmissions are available. These transmissions’ quietness and smooth operation also add to their popularity in areas where the noise of the machine is intrusive.

Q: How do I maintain Guomao’s cycloidal gear reducer for optimal performance?

A: It’s important to maintain your Guomao’s cycloidal gear reducer in order to maintain its smooth functioning during operation. One of the most wonderful features of these gear reducers is simply how simple it is to remove and reinstall them for maintenance. There are periodic maintenance procedures involving examining parts such as the output shaft, fastening ring, small end cover, machine base, pin shaft and pin sleeve to ensure that they’re all in good working order. The decision to utilize premium materials such as bearing steel in transmission components improves their strength and lifespan significantly. This material selection reduces operational friction, thereby decreasing mechanical strain. To ensure optimal performance of your cycloidal gear reducer, operate it within its specified limits and avoid excessive stress. This practice prevents damage while ensuring longevity and efficiency.