Maximizing Efficiency with Parallel Shaft Gearbox Solutions

Exploring the Benefits of Parallel Shaft Gearboxes

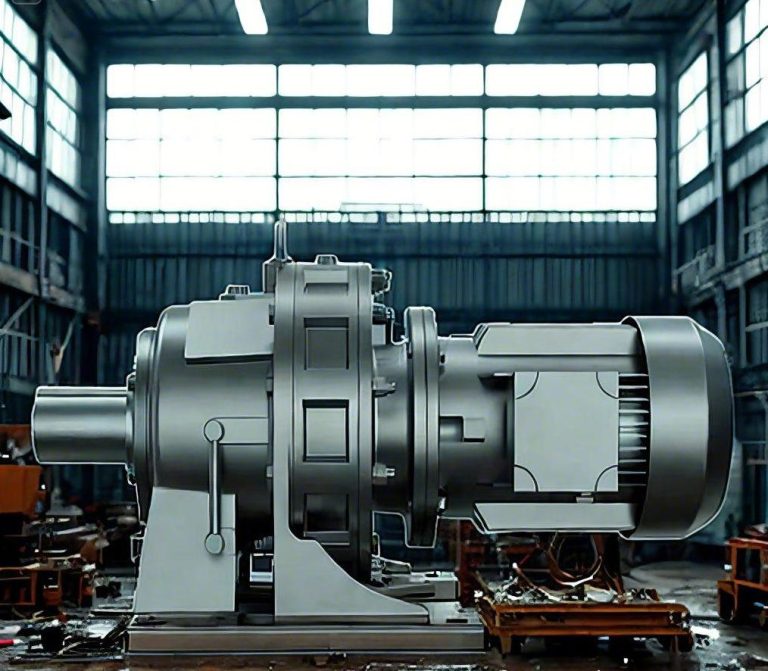

In industrial applications where equipment is subject to significant use, parallel shaft gearboxes become highly significant when it comes to increasing efficiency and performance. That they are compact and smaller in dimensions are advantages that accrue from their use of the planetary transmission principle. It becomes possible for input and output shafts to operate parallel to the axis making these gearboxes most suitable where space is minimal.

Another key advantage is their high reduction ratio and efficiency. A single-stage gearbox is capable of a 1:87 reduction ratio with an efficiency of over 90%, while multi-stage models achieve ratios up to 33,000 for a range of torques and speeds.

In addition, parallel shaft gearboxes facilitate assembly, disassembly, and maintenance by modular design and standardization of components. This characteristic minimizes disruptions during maintenance tasks. Guarantees a prompt return to full machinery operation.

Key Features of Guomao’s Parallel-Shaft Helical Geared Motor

Guomao’s GF Series Parallel-Shaft Helical Geared Motor is highly regarded in the market for its features. Its modular design allows connection with different types of motors or alternative power sources. This adaptability empowers users to customize solutions based on their needs.

Shafts of GF series geared motors are all parallel to each other. Units of the GF series all consist of two or three stages of helical gears. It features helical gears and parallel shaft combinations. The output shafts include hollow shafts with locking discs and solid shafts. The gear system provides varying transmission ratios to meet operational requirements adequately. Power ranges from 0.12 kW to 200 kW and output torque of up to 50 kNm for light-duty application and heavy-duty applications.

Guomao’s gear motor is known for its performance and quiet operation levels. The accurate machining and assembly procedures play a role in achieving this guarantee of seamless functioning across various industrial environments.

Additionally, the gear motor is designed for long-term durability, with key components lasting over 25,000 hours with regular maintenance. This robustness makes it a cost-effective solution for industries prioritizing long-term operational efficiency.

Implementing Guomao’s Parallel-Shaft Helical Geared Motor in Various Industries

Application in Manufacturing and Production Lines

In assembly lines and in applications, Guomao’s Parallel Shaft Helical Geared Motor plays a significant role in productivity improvement. Due to its capacity to support radial loads, it is best utilized in conveying machinery like auger conveyors, bucket conveyors and belt conveyors. These systems profit from the motor’s transmission efficiency, which guarantees seamless material handling operations.

The versatility of the motor is shown by its ability to run in both clockwise and counterclockwise directions which adds flexibility to how production lines can be set up.Its strong build also allows it to work well in temperatures between -10℃ and 40℃ making it adaptable to manufacturing settings.

Technical Insights into Guomao’s Parallel Gearbox Technology

Understanding the Mechanics of Parallel Shaft Gearboxes

Parallel shaft gearboxes, such as the GF Series Parallel-Shaft Helical Geared Motor, operate on principles of helical gear meshing and modular design to deliver efficient power transmission. Here’s a breakdown of their mechanics and key features:

Gear Arrangement & Power Transmission

The parallel shafts with helical gears ensure smooth engagement due to the angled teeth, this feature reduces noise and vibration compared to spur gears. And the power flows through two or three-gear stages, enabling high torque output (up to 50 kNm) and wide transmission ratios (1.26—33,000).

Structural Advantages

The parallel shaft gearboxes are highly modular. Components are standardized for flexible configurations, supporting multiple installation types (e.g., foot-mounted, flange-mounted, and shaft-mounted). Hollow or solid output shafts accommodate diverse coupling methods. The high-strength cast iron housings and gas-carburized gears enhance resistance to wear, it ensures a service life exceeding 25,000 hours under normal conditions.

Efficiency & Performance

Due to the rolling friction of helical meshing, more than 95% efficiency is achieved in the gear unit, minimizing energy loss and greatly improving efficiency. So it is suitable for bidirectional operation and 24-hour continuous use in applications like conveyors, hoisting systems and slurry pumps.

Installation and Maintenance Considerations

Ensuring optimal performance and longevity of Guomao’s parallel shaft gearboxes requires proper installation and regular maintenance. The flexible design of these gearboxes makes it simple to connect them with motor types or power inputs for customizable options.

During installation of the gearbox, it must be mounted on a non-vibrating base. If you have to mount it on an angle, make the angle as close to ±15°as possible. The gearboxs smart design makes regular upkeep easier by enabling assembly disassembly and maintenance. This design feature cuts down on service downtime. Keeps your machinery running smoothly.

In addition to that point suggested that users to follow rules related to the surroundings where they use Guomao’s geared motors which perform well in temperatures between -10℃ and 40℃ and at elevations up to 1,000 meters above sea level.

Frequently Asked Questions about Guomao’s Parallel-Shaft Helical Geared Motor

Q: How Does Guomao Ensure Quality in Its Gearbox Products?

A: Guomao guarantees the excellence of its Parallel Shaft Helical Geared Motor through the implementation of modular designs that facilitate compatibility with a range of motors and input power sources to meet diverse needs effectively. The incorporation of cast iron for housings and gears treated with gas carburizing processes ensures superior load-bearing capacity and longevity. Furthermore, each essential part undergoes meticulous machining and precise assembly processes resulting in noise and optimal performance ensuring the longevity and dependability of its gearboxes for prolonged periods of operation.

Q: What Are the Customization Options Available for Specific Industry Needs?

A: Guomao offers a range of customization to meet specific industry demands. Its gearbox structures are modular in nature, which offers provision for flexible configurations with different types of input shafts and types of mounting such as foot-mounted, B5 flange-mounted, B14 flange-mounted, shaft-mounted and torque arm-mounted mounting. All this flexibility allows the gearbox to be tailored to meet varied operational requirements in various industries.

Q: What Are the Considerations When Using Guomao’s Motor in Environments with High Levels of Starting and Stopping Operations?

A: In settings where there are interruptions and restarts happening regularly it’s crucial to take into account the motors robust overload capability and ability to withstand impacts.These characteristics make it ideal for tasks that involve alterations in speed or direction. Moreover making sure the alignment is correct during setup will aid in sustaining peak performance in situations.